Superior Battery Technology

High-Performance Lithium Batteries:

Empowering Electric Mobility with Exceptional Energy and Durability

Lithium-based batteries are the technology of choice for electric mobility applications. They store significantly more energy than all other batteries, they maintain a high current, they do not lose their charging capacity, they supply power reliably, and have no memory effect. They also have a much longer useful life than lead-based batteries.

Torqeedo has been a pioneer in the development of lithium batteries for marine applications since 2005. As we continuously improve our technology, we offer the most comprehensive and integrated protection and safety concept for lithium batteries on the market – coupled with performance and convenience.

LiFePO or LFP (lithium iron phosphate) and LiNMC (lithium nickel manganese cobalt) are both types of lithium-ion batteries. LFP and LiNMC batteries have unique sets of benefits and drawbacks. At Torqeedo, we use both chemistries for different boating applications.

LiFePO / LFP

LFP batteries have a lower energy density and discharge rate, though LFP battery performance has rapidly improved both in cost and volumetric energy density (Wh/L) over the past few years. If the vessel is not particularly weight-sensitive and batteries are permanently installed, LFP batteries may offer significant price and longevity benefits.

LiNMC

LiNMC chemistry offers the highest energy density – the most power with the least weight – and the highest discharge rate. This makes it the best choice for portable and integrated batteries, like our Ultralight, Travel, and Power batteries, and for very weight-sensitive Deep Blue applications.

High Capacity Batteries

Deep Blue Battery 80 – NEW –

The latest generation of lithium iron phosphate (LFP) batteries delivers industry-leading volumetric energy density by leveraging cell-to-pack architecture. The result? Double the energy storage in a smaller footprint. Ultimate durability, safety and reliability is backed by a ten-year capacity warranty for recreational and commercial use.**

** at least 4.000 Cycles @ 75% DoD, ϑ: 25°C or 3.750 Cycles @ 80 % DoD, ϑ: 25°C or 3.000 Cycles @ 100% DoD, ϑ: 25°C

- LFP has a long cycle life and is resistant to high temperatures.

- LFP has a constant power output and a continuous and flat voltage curve. Because the current is so stable, components may be designed to meet their optimal operating point.

- LFP batteries are made with abundant raw materials, avoiding much of the high cost and ethical and environmental problems associated with mining critical metals.

- The Deep Blue Battery 80’s cell-to-pack architecture is an advanced approach to battery assembly in which individual battery cells are directly integrated into a pack without the need for intermediate modules or components. This advanced construction offsets the lower energy density of LFP batteries and enables a more compact footprint that is easier to install in many boats.

- LFP batteries have a higher temperature threshold before thermal runaway and a lower reactivity if it occurs.

Deep Blue Battery 40

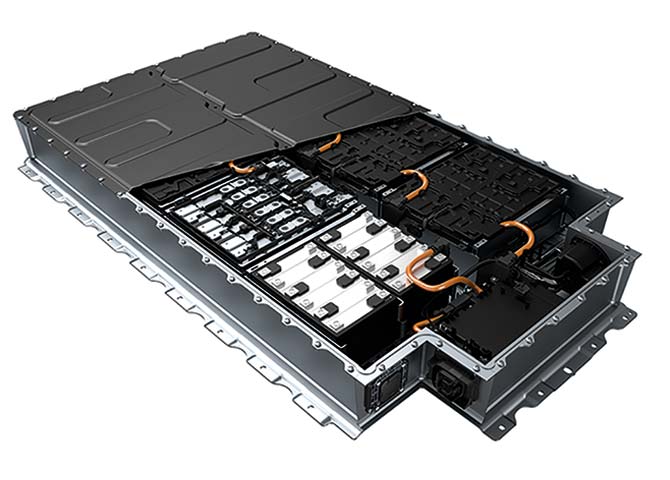

Cooperation between BMW i and Torqeedo has made state-of-the-art automotive battery engineering available for the marine market. The battery technology introduced in the BMW i3 can power your Torqeedo drive.

- LiNMC chemistry delivers highest energy density and highest discharge rate – the most power for the least weight, delivered as quickly as possible.

- Prismatic cells, as found in the Deep Blue 40 Battery, have many advantages. However, they must be assembled extremely accurately in a very robust frame for a long service life (Otherwise charging and discharging would, over time, lead to the cells expanding and collapsing very slightly and cause them to age prematurely)

- Backed by a nine-year capacity warranty for recreational use*

- The very rugged design is ideal for high-speed boat applications that place high demands on shock resistance

-

State-of-the-art BMS technology

-

Developed to ASIL C standards as used in the automotive industry for maximum safety

-

Qualification and acceptance testing at a far higher level than is typical in the boating industry

-

Cools the battery to ensure high performance and a long service life even in high ambient and water temperatures

-

In all climate zones anywhere in the world

-

Very high energy density

-

Prismatic cell design allows efficient cooling, a compact form, even temperature distribution within the battery and an extremely rugged structure

-

Robust protective aluminium housing with safety vent

-

From the automated production process of Samsung SDI, a leading manufacturer of lithium battery cells

-

Over a larger surface and therefore stronger and more powerful than conventional spot – welded cell connections

-

The battery is waterproof to IP67. In the unlikely event of excess pressure developing in a cell, the prismatic cells can release the excess pressure through a valve. This is a significant safety advantage over foil-welded cells and pouch cells. The pressure safety disc allows gases to escape and ensures the battery stays waterproof in normal operation

Low Voltage Power Lithium Batteries

A class of its own in lithium batteries for boats: 70% more energy density and 50% longer cycle life than typical lithium LiFePO4 batteries

Integrated information system identifies the battery and communicates with the Cruise onboard computer

The service life of a lithium battery is determined by time and, to a lesser extent, the number of charging cycles. The capacity loss over time is about 2-4% per year at an ambient temperature of 25°C. The aging process is accelerated if the battery is exposed to high temperatures. Lithium batteries can be used even when it is hot, but should be stored at a cooler temperature when possible.

Lithium Battery Safety

Besides performance, safety plays an important role for lithium batteries.

Battery management system (BMS) with redundant safety features: unlike lead-based batteries, lithium batteries always need a BMS to perform balancing and safety functions. If electronic components of the BMS fail it can itself become a safety problem for the battery. That's why there is hardware backup for all safety-relevant components in Torqeedo batteries. Incidentally, this is also stipulated in the automotive industry, in aerospace and for medical technology.

Safe, individual cell packaging: Torqeedo only uses individually welded cells or modules which are equipped with multiple safety mechanisms. Other forms of packaging such as foil-sealed cells ("coffee bags") offer a lower standard of safety as they afford less effective protection against internal short circuiting within the cells. (An exception here are cells with ceramic separators, which also provide safe packaging, but these are extremely expensive and very seldom used.)

Clean, precision production processes on the part of the cell manufacturers. Torqeedo only uses cells sourced from reputable manufacturers in Japan and the USA.

Waterproof to IP67: Water in lithium batteries can lead to various problems such as corrosion of the BMS hardware or the creation of electrolytic gas. Lithium batteries on board a boat should therefore be waterproof.